What is a thermopile vs thermocouple

Jun 04, 2025TL;DR Thermocouples are robust, fast, and excellent for high-contact and high-temperature uses. Thermopiles combine many thermocouples (or junctions) to increase output and sensitivity, ideal for non-contact IR and small temperature-difference detection. This guide covers principles, comparison metrics, application maps, selection checklists, trends, and how Focusensing’s products match real engineering needs.

A thermocouple is a temperature sensor made from two dissimilar metals joined at one end (the hot junction). A temperature difference between the hot junction and a reference (cold) junction generates a small voltage via the Seebeck effect. That voltage is then translated into temperature with calibration and often cold-junction compensation. :contentReference[oaicite:0]{index=0}

Key traits: wide temperature range, very fast response, simple structure, low cost — but low single-junction output (microvolts), so good signal conditioning and cold-junction compensation are required. :contentReference[oaicite:1]{index=1}

A thermopile is essentially many thermocouple junctions arranged electrically in series (and thermally in parallel) so their voltages add up — increasing output and sensitivity for small temperature differences or radiation detection (IR). Thermopiles are widely used in non-contact thermometers, IR detectors, heat-flux sensors and energy-harvesting prototypes. :contentReference[oaicite:2]{index=2}

Key traits: higher aggregated output, better small-ΔT detection, optimized for IR absorption; slower thermal response (greater thermal mass/thermal balancing), more complex packaging and calibration. :contentReference[oaicite:3]{index=3}

Below is a concise table comparing typical performance dimensions. Replace numeric “typical” values with your lab or product data for exact claims.

| Metric | Thermocouple (typical) | Thermopile (typical) | Engineering note |

|---|---|---|---|

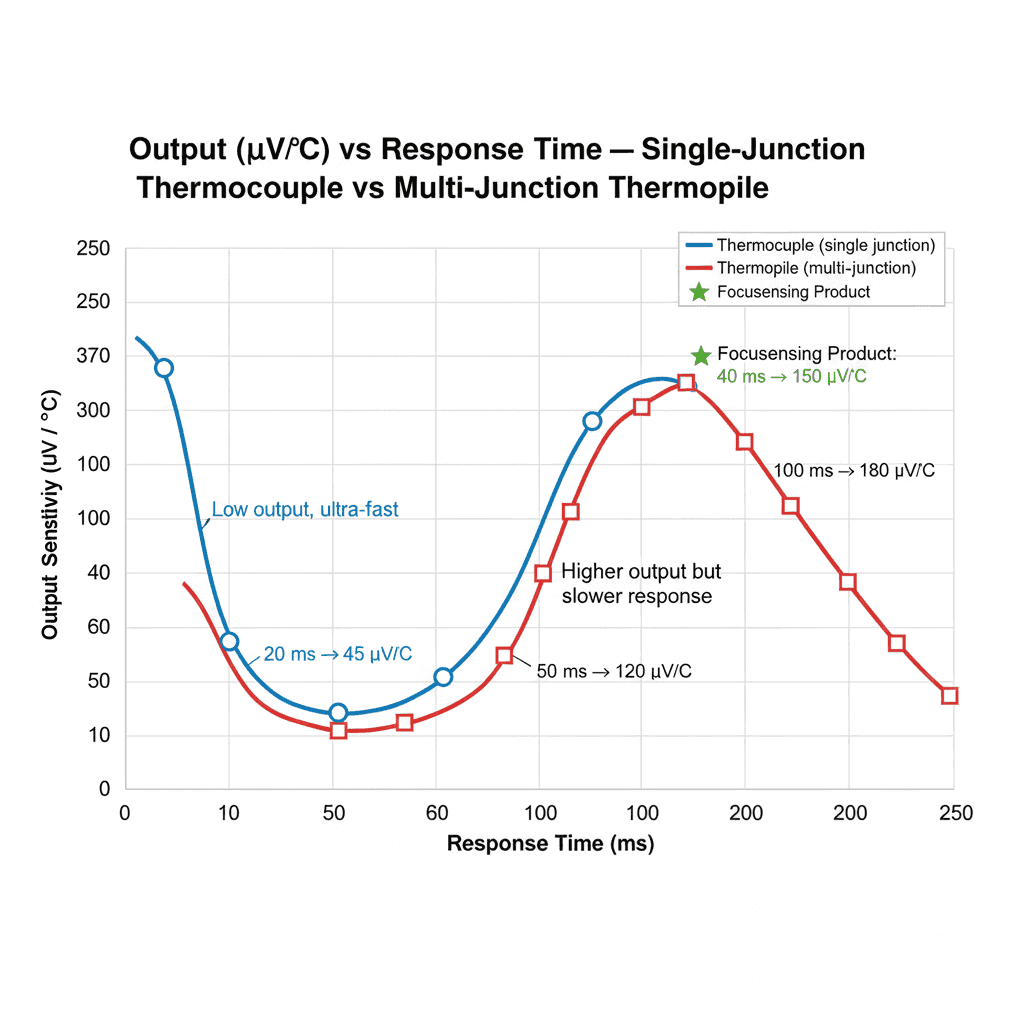

| Output (µV/°C) | ~5–50 µV/°C (single junction) | Sum of many junctions → tens → hundreds µV/°C | Higher aggregated output eases amplification |

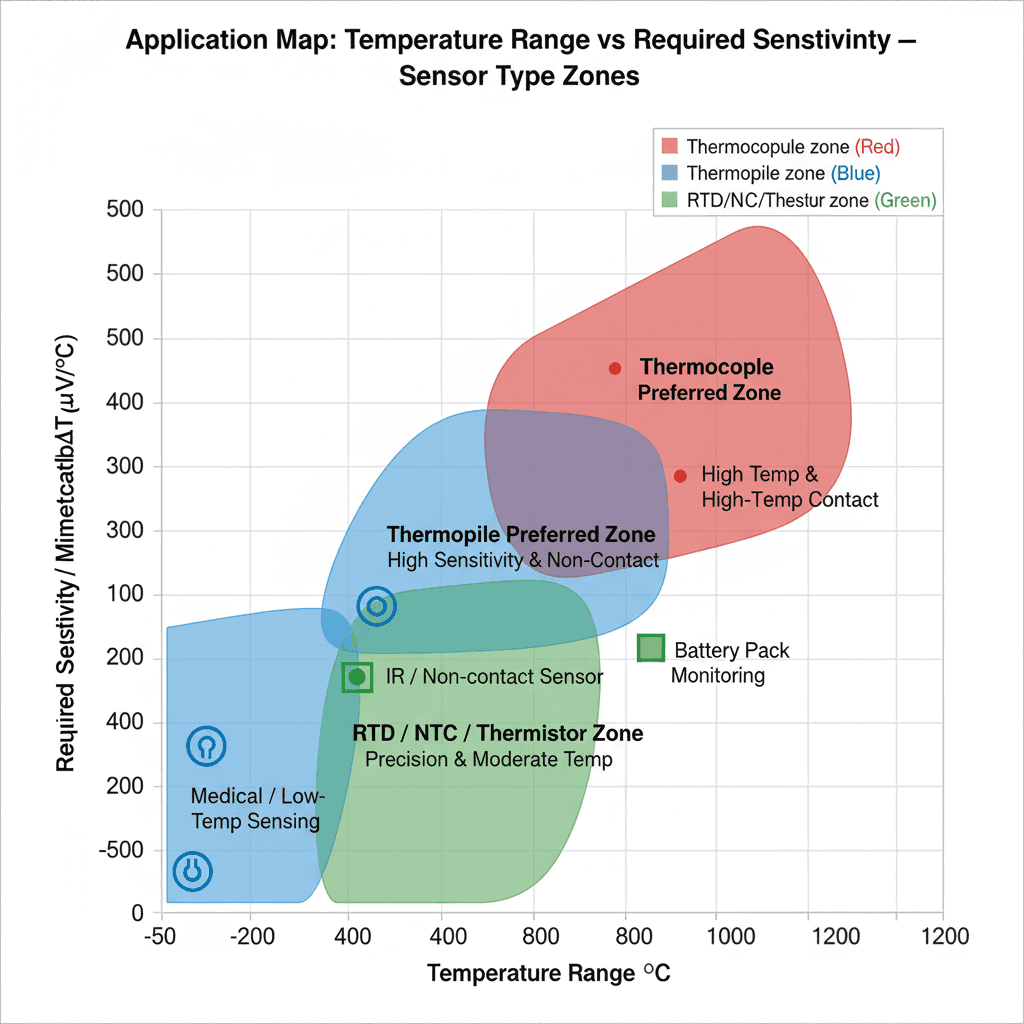

| Temperature range | Very wide, from cryogenic up to >1000°C (type dependent) | Usually limited to lower-moderate ranges (material/packaging dependent) | Use thermocouple for extreme high-T |

| Response time | Fast: ms range | Slower: tens → hundreds ms or more | Control loops often prefer thermocouples |

| Sensitivity / SNR | Lower (single junction) | Higher (multi-junction) | Thermopiles excel at small ΔT and IR sensing |

| Cost & complexity | Low, simple | Higher: junction count, absorber coatings, packaging | Balance cost vs system-level gain |

Notes: thermopile operation and aggregated junction behavior are described by standard thermopile references. :contentReference[oaicite:4]{index=4}

| Scenario | Typical Requirements | Recommended Sensor | How Focusensing helps |

|---|---|---|---|

| Industrial furnaces & high-T contact | Very high temp, ruggedness, fast response | Thermocouple (Type K/J/S etc.) | Custom thermocouple probes and sheaths from Focusensing for high-T & harsh environments. :contentReference[oaicite:5]{index=5} |

| Non-contact IR thermometers & fever screening | Radiation sensing, small ΔT sensitivity, calibrated IR measurement | Thermopile (MEMS thermopile modules) | Focusensing MEMS thermopile modules with IR absorber and calibration options. :contentReference[oaicite:6]{index=6} |

| Automotive / EV battery monitoring | Moderate temp range, many sensors, reliability | Thermocouple / RTD / NTC depending on location | Focusensing NTC/RTD & thermocouple lines for battery, thermal management. :contentReference[oaicite:7]{index=7} |

Industry examples (thermopile adoption in sensors and CO₂ detectors) demonstrate thermopile modules’ industry traction for medical and environmental sensing. :contentReference[oaicite:8]{index=8}

Recent trends include MEMS thermopile miniaturization (lower thermal mass → faster response), improved absorber materials, digital integration (I²C, SPI modules with onboard calibration), and energy-harvesting micro-thermopiles for IoT. Academic and industrial developments continue to push MEMS thermopile performance and integration. :contentReference[oaicite:10]{index=10}

A: Not always. For extreme temperature ranges, harsh contact environments, or high-speed control, thermocouples are often more suitable. For non-contact IR and small ΔT detection, thermopiles often outperform a single thermocouple. :contentReference[oaicite:11]{index=11}

A: Thermopiles usually have larger thermal mass (absorber layers, multiple junctions) and require thermal balancing, which increases response time compared to bare thermocouple junctions. :contentReference[oaicite:12]{index=12}

A: Increase junction count (if feasible), optimize absorber and thermal isolation, use low-noise amplifiers and differential measurement techniques. :contentReference[oaicite:13]{index=13}

Focusensing is an ISO-certified sensor manufacturer specializing in temperature, humidity and position sensing components, custom sensor modules, and OEM solutions. Our portfolio includes thermocouples (K/J/T types), NTC/PTC thermistors, RTDs (PT100/PT1000), and MEMS thermopile modules optimized for industrial, automotive, medical and IoT applications. :contentReference[oaicite:14]{index=14}

If you’d like, Focusensing can provide product datasheets, calibration certificates, and sample units for evaluation. (Consider linking to a PDF or product page on your site.)